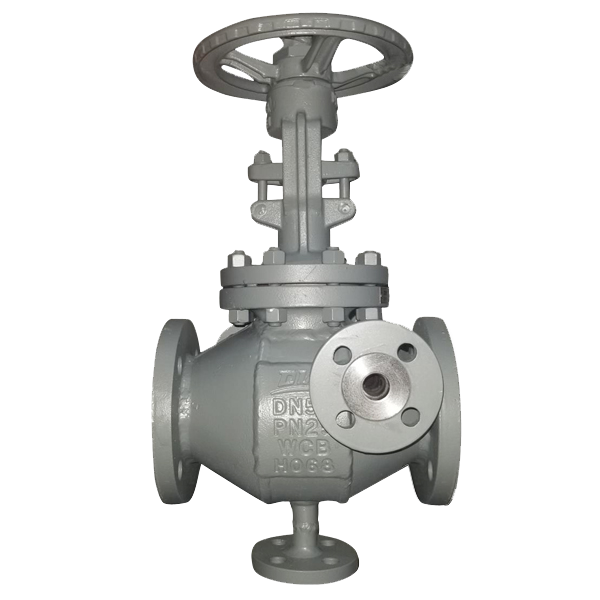

The Heating Jacket Gate Valve is widely used in industries such as petrochemical, chemical, and pharmaceutical. Its primary function is to maintain the temperature of the valve and its internal fluid by circulating a heating medium within the jacket, preventing the fluid from solidifying or freezing due to temperature drop.

1. Advantages of the Heating Jacket Gate Valve

(1) Maintaining Fluid Temperature

The heating jacket gate valve maintains the temperature of the valve body and internal fluid through the heating medium circulating within the jacket (such as steam, hot oil, etc.), preventing the medium from solidifying or freezing due to temperature drop. This is particularly important for high-viscosity, crystallizable, or solidifying media.

(2) Preventing Pipeline Blockage

In low-temperature environments, certain fluids are prone to crystallizing or solidifying within the pipeline and valve, leading to blockages. The heating jacket gate valve effectively prevents this issue by heating the jacket, ensuring smooth operation of the pipeline system.

(3) Enhancing Process Efficiency

By maintaining the fluid's flowability, the heating jacket gate valve can significantly improve process efficiency, reducing downtime and production losses. This is especially beneficial in continuous production processes, offering notable economic advantages.

(4) Extending Equipment Lifespan

The design of the heating jacket gate valve reduces equipment wear and maintenance frequency caused by low temperatures, thereby extending the lifespan of the valve and associated equipment. This also helps lower maintenance costs.

(5) Wide Range of Applications

Heating jacket gate valves are suitable for various industries, including petrochemical, pharmaceutical, and food processing. They are capable of meeting the demands of various complex operating conditions and offer strong adaptability.

2. Limitations of the Heating Jacket Gate Valve

(1) Higher Costs

Due to the complex structure of heating jacket gate valves, their manufacturing costs are relatively high. Additionally, the need for heating media and related equipment results in higher initial investment and operating costs compared to standard valves.

(2) Strict Installation Requirements

The installation of heating jacket gate valves requires careful consideration of the heating medium's piping connections and insulation measures. The process is relatively complex and demands higher technical skills from the installation personnel.

(3) Complex Maintenance

Maintaining a heating jacket gate valve involves not only the upkeep of the valve itself but also the care of the heating jacket and the heating medium. This adds complexity to maintenance tasks and requires specialized technical support.

(4) Higher Energy Consumption

A heating jacket gate valve requires a continuous supply of heating medium, resulting in higher energy consumption. In situations where energy costs are high, using a heating jacket gate valve may increase operating expenses.

(5) Application Limitations

Although heating jacket gate valves are suitable for various industries, their primary application is in processes that require maintaining the temperature of fluids. In situations where heating or insulation is not needed, using a heating jacket gate valve may not be cost-effective.