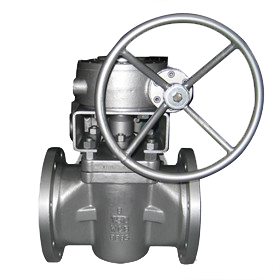

Sleeve type plug valves, known for their excellent sealing performance and precise fluid control capabilities, are widely used in various industrial sectors. Proper installation is crucial for ensuring the valve's normal operation and extending its service life.

1. Preparation Before Installation

(1) Verify Specifications and Model

Before installation, check that the valve's specifications and model meet the system requirements. Ensure that the valve's size, pressure rating, and materials are compatible with the pipeline system's specifications.

(2) Inspect Valve Condition

Examine the valve's appearance and operational status. Ensure that the valve is free from damage, deformation, or other noticeable defects. Verify that the sealing between the plug and sleeve is intact and functioning properly.

(3) Prepare Tools and Materials

Prepare the necessary tools and materials for installation, including wrenches, screwdrivers, sealing gaskets, bolts, washers, and lubricants.

(4) Clean the Piping and Valve

Remove any impurities and debris from the inside of the pipes to ensure that there are no foreign objects at the valve and pipe connections, which could affect the sealing performance.

2. Installation Steps

(1) Position the Valve

Ensure that the valve is correctly positioned within the piping system. Determine the installation direction of the valve according to system requirements. Typically, the flow direction of the valve will be indicated on the valve itself, so make sure the fluid flow direction matches the valve's indication.

(2) Install the Gaskets

Place appropriate gaskets at the flange connections of the valve. The gasket material should be compatible with the medium and capable of withstanding the operating temperature and pressure.

(3) Connect the Valve

Align the valve with the pipeline flanges and secure the valve to the pipeline using bolts. Employ a diagonal, alternating tightening pattern to ensure even bolt loading and avoid flange distortion or poor sealing.

(4) Check Valve Alignment

Before tightening the bolts, check the alignment of the valve with the pipeline. Ensure that the valve's centerline is aligned with the pipeline's centerline to avoid damage or leakage caused by misalignment.

(5) Tighten the Bolts

Use a wrench to evenly tighten the bolts to the specified torque value. Be careful not to overtighten, as this could damage the flanges or the sealing gasket.

(6) Check Valve Operation

After installation, manually operate the valve to ensure smooth opening and closing. Verify that the valve plug moves freely without obstruction and that the sealing performance is effective.

(7) Conduct System Testing

Start up the system and gradually increase the system pressure. Check for any leaks at the valve and its connections. Ensure that the valve operates correctly under working pressure and temperature conditions.

3. Maintenance and Precautions After Installation

(1) Regular Inspections

Regularly inspect the condition of the plug valve to ensure its sealing performance and operational status are in good condition. Particularly during the initial phase of system operation, increase the frequency of inspections to promptly identify and address potential issues.

(2) Avoid Overloading

Avoid operating the valve beyond its designed pressure and temperature limits. Overloading can lead to valve damage or premature failure.

(3) Cleaning and Lubrication

Regularly clean and lubricate the valve, especially when handling corrosive or particulate-laden media, to maintain optimal operating conditions.

(4) Follow Operating Guidelines

Adhere to the valve’s operating guidelines and the manufacturer’s maintenance recommendations to prevent valve failures due to improper operation.